Maschinenfabrik Gustav Eirich GmbH & Co KG

Tradition and Innovation – since 1863

Preparation technologies for lithium-ion batteries

From the world-market leader for preparation systems in the lead-acid battery field

EIRICH – trend-setter in the field of preparation systems for batteries

Gaining a competitive edge with the right technology

The right preparation technology is a major precondition for advanced battery systems with very high energy densities, endurance and safety. And the right partner is indispensable for anyone wishing to offer modern and environmentally friendly products on a long term basis. At the same time you benefit directly from our research and development activities. Because EIRICH and renowned companies, universities and competence networks have been working jointly for decades on future battery concepts. Regardless of whether you are active in the electromobility field or in the development of stationary energy storage concepts, EIRICH will always be able to offer you the best preparation solution for your future battery concepts.

The global battery market holds unimagined possibilities for companies. With our tailor-made technical solutions we would be glad to help you make in the most of these possibilities.

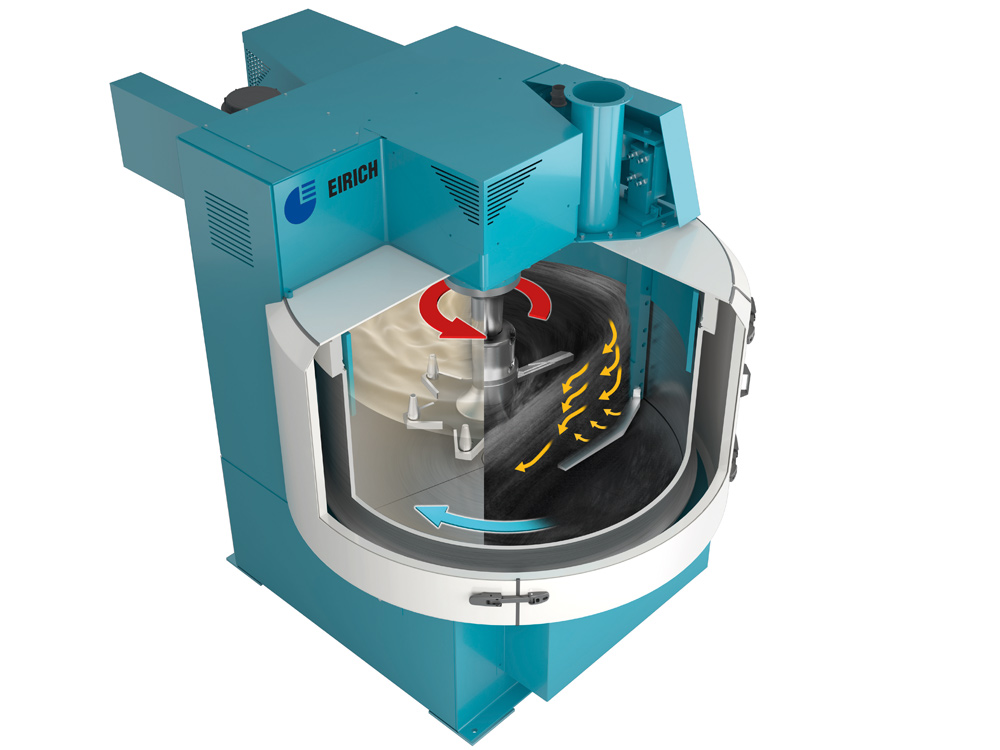

Innovative EIRICH preparation technology

No matter which energy storage systems ultimately prevail, the key to your success will always be the right preparation technology

- Simple and smart Process technology

- Higher output performance compared to other mixing technologies

- Highest Flexibility in terms of raw materials and processing routes

- Continous or batch wise supply to coating line possible

- Very short batch time (minutes instead of hours)

- Excellent scale-up capability

- Less energy consumption in comparison to state-of-the-art technologies

- Potential for increase of electrode performance

- EIRICH ContiFeeder process combines best out of batch and conti processing

- Less required space / area for plant / factory

- Reduced investment – Reduced running costs

- EIRICH mixing technology suitable for

– Next-Generation Electrode production (Extrusion, Dry Coating, Pressing)

– All-Solid State Batteries

The EIRICH GROUP is a family operated corporate group in the specialized mechanical engineering field headquartered in Hardheim, Baden Württemberg. As a worldwide leader in machine manufacturing specializing in material processing, EIRICH has designed, conceptualized, and produced advanced manufacturing technologies for mixing, granulating, dispersing, kneading, reacting, tempering, and milling since 1963. Solutions for process technology and automation complete EIRICH’s portfolio. Over 1300 employees are actively creating the future of process engineering at 15 distribution and manufacturing locations worldwide. EIRICH’s advanced technical solutions are primarily used in the areas of battery systems, energy storage, environmental technology, metallurgy, casting, agricultural chemistry, ceramics, and others.