Summary:

Labelled “the most important and the least understood” part in a lithium ion battery (LIB), the solid electrolyte interphase (SEI) is believed to have a major influence on the performance of LIBs. This layer of hardly soluble electrolyte decomposition products provides sufficient electronic insulation at the negative electrode|electrolyte interface and hence protects the cell from continued electrolyte decomposition. Similarly, at the positive electrode|electrolyte interface, the cathode electrolyte interphase (CEI) is formed.

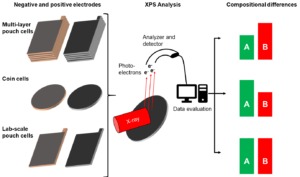

Here, X-ray photoelectron spectroscopy (XPS) is used to determine chemical composition and thickness of SEI and CEI in dependence of cell format. XPS analysis of graphite || LiNi0.6Mn0.2Co0.2O2 – based LIB cells of three different cell formats is carried out. The cell types are 2032 coin cells, single layer lab-scale pouch cells and multi-layer pouch cells. SEI and CEI are analyzed by XPS after electrochemical formation.

Compositional differences between the cell formats are found for both negative and positive electrodes. Within the SEI of multi-layer pouch cells, more organic species but less LiF is found, indicating a thicker organic SEI layer compared to the other cell formats. This is confirmed by separate calculation of inorganic and organic SEI thickness.

On the positive electrodes, the amount of LiF is also lower for multi-layer pouch cells. A thick CEI layer has formed on lab-scale pouch cells and especially coin cells, while the CEI thickness of the multi-layer pouch cells is negligibly small. As thermo-chemical rather than electrochemical reactions are considered to be mainly responsible for the CEI, the high amount of LiF in coin and lab-scale pouch cells was further investigated. For the initial experiments, only multi-layer pouch cells were oven-dried after the stack had been assembled. By additionally drying the cell housing of the other cell formats as well, it is shown that even small amounts of residual water remaining on the cell housing under dryroom conditions may heavily influence XPS results. Likely, the residual water from the cell housing instantaneously reacts with the conducting salt, LiPF6, to form LiF on the electrode surfaces.

With the additionally dried cells, further XPS investigations are conducted. Here, the LiF content on both positive and negative electrodes is notably smaller compared to the non-dried cells. While there are still differences, the results of dried coin and lab-scale pouch cells resemble those obtained from multi-layer pouch cells. The CEI thickness decreases significantly, e.g. from 2.5 ± 0.3 nm to 0.4 ± 0.1 nm in case of the coin cells. Furthermore, a thicker organic SEI layer is found after drying. Possibly, this thermo-chemical contribution to the SEI, leading to a large amount of highly insulating LiF, acts as disturbing factor which suppresses the formation of organic species.

State-of-charge vs. open-circuit-voltage plots show a larger voltage hysteresis in case of the non-dried cells. Both charge and discharge GITT pulse resistance is lower for dried cells. A thorough electrochemical investigation, e.g. EIS investigations and the influence of the residual water on cell performance, will be conducted.

We are happy to forward your request / feedback.