Summary:

Fast-charging of lithium-ion batteries at low temperatures and high states of charge (SOC) can lead to accelerated ageing. The primary mechanism that causes the loss of cyclable lithium inventory under those conditions is the irreversible deposition of metallic lithium on the surface of the graphitic anode. The more significant share of the metallic lithium is getting stripped at subsequent discharges or intercalates chemically. However, a part of the deposited lithium reacts with the electrolyte or is getting electrically isolated and hence lost for the storage mechanism. Detecting and avoiding reversible lithium deposition (LD) can thus prevent accelerated cell ageing through irreversible lithium plating. An improved method for the detection of critical charging conditions will result in advanced fast-charging strategies. Since it is already well known that the thickness of lithium-ion cells can be used to diagnose LD [1, 2], this study intends to connect the volumetric changes during the relaxation to its voltage behaviour.

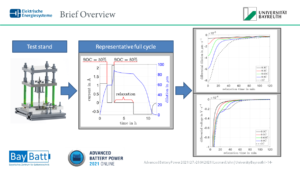

Commercial RouteJade SLPB526495 pouch cells with a graphite/NMC chemistry are cycled at -5 °C under constant pressure while the cell’s thickness and voltage are measured. Special attention is given to the relaxation following a charging process with high currents at a high sstate of charge (SOC) between 50% and 80%. The cell thickness is measured with a contact displacement sensor with a resolution of 0.1 μm. All measurements are conducted in a self-developed test stand to provide a homogenous and constant pressure on the cell surface. The experiments are carried out with a pressure of 0.2 MPa or 0.4 MPa and increasing charging rates from 0.3C to 1C in the mentioned SOC window. After completion of the charging process, the cells are relaxed for four hours.

During the relaxation, a cell contraction can be observed for all applied C-rates, which is explained by the homogenisation of the anode’s degree of lithiation. Due to fast-charging, a high gradient of solid-phase concentration exists along the particle radius and the depth of the electrode. The homogenisation of these gradients at a high SOC results in a contraction of the cell [2]. At charging rates with a visible feature for LD in the voltage analysis as proposed by Schindler et al. [3], a reproducible anomaly in the gradient of the contraction behaviour can be observed. The anomaly is linked to the chemical intercalation of reversible LD into the graphite particles, which is completed prior to the homogenisation of graphite lithiation [4].

On the one hand, the anomaly can be used to detect only the occurrence of LD shortly after the end of charge. On the other hand, the elapsed time until the gradient of the dilation returns to an unsuspicious behaviour correlates with the criterion of the differential voltage (DV) analysis. This leads to the conclusion that the anomaly of contraction behaviour can be used to determine the time until the deposited lithium is mostly intercalated. The dilatometry analysis even shows this anomaly even for those charging rates where reversible LD is likely but not visible in the voltage analysis.

In conclusion, the dilatometric analysis of lithium-ion cells during the relaxation after fast charging can be used as a detection method for reversible LD. It even shows a higher sensitivity for the detection of critical charging conditions for the studied cells compared to the DV analysis.

References

[1] B. Bitzer and A. Gruhle, “A new method for detecting lithium plating by measuring the cell thickness,” Journal of Power Sources, vol. 262, pp. 297–302, 2014, doi: 10.1016/j.jpowsour.2014.03.142.

[2] M. Bauer, M. Wachtler, H. Stöwe, J. V. Persson, and M. A. Danzer, “Understanding the dilation and dilation relaxation behavior of graphite-based lithium-ion cells,” Journal of Power Sources, vol. 317, pp. 93–102, 2016, doi: 10.1016/j.jpowsour.2016.03.078.

[3] S. Schindler, M. Bauer, M. Petzl, and M. A. Danzer, “Voltage relaxation and impedance spectroscopy as in-operando methods for the detection of lithium plating on graphitic anodes in commercial lithium-ion cells,” Journal of Power Sources, vol. 304, pp. 170–180, 2016, doi: 10.1016/j.jpowsour.2015.11.044.

[4] V. Zinth et al., “Lithium plating in lithium-ion batteries at sub-ambient temperatures investigated by in situ neutron diffraction,” Journal of Power Sources, vol. 271, pp. 152–159, 2014, doi: 10.1016/j.jpowsour.2014.07.168.

We are happy to forward your request / feedback.